Bipolar plates are critical components in PEM fuel cells, guiding reactant gases, managing water, and conducting current between cells. They also represent a significant share of the total stack cost and value. IDTechEx forecast the market for PEM fuel cell bipolar plates to exceed US$500M by 2036, and so the material selection is increasingly strategically important.

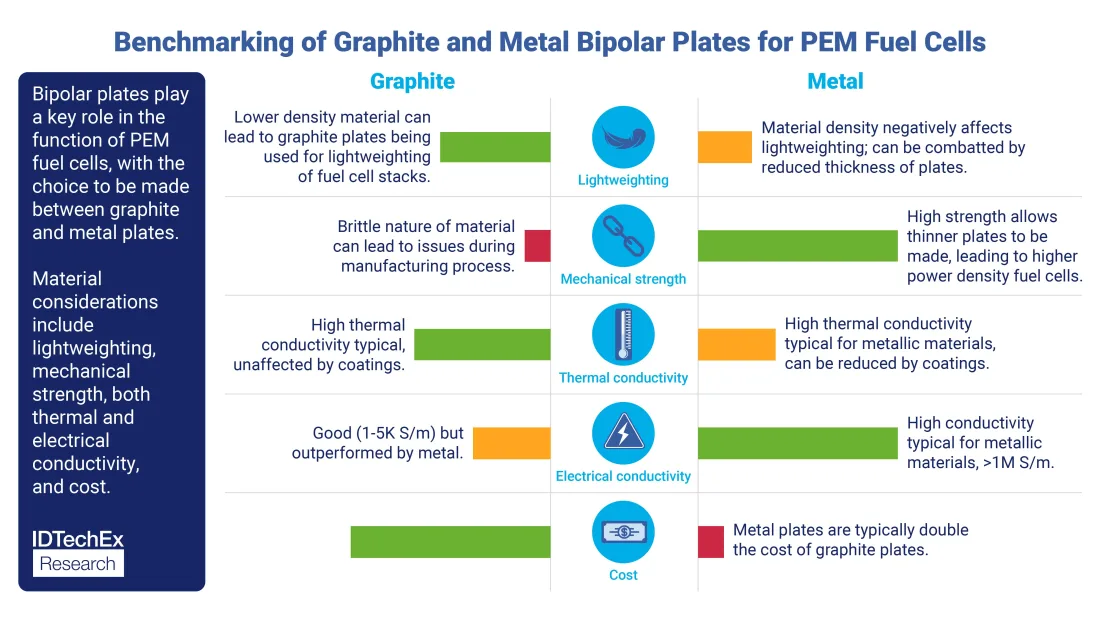

Today, a strong materials battle exists between graphite and metal plates. Graphite offers excellent corrosion resistance and thermal conductivity, while metal enables thinner and stronger plates. This competition continues to shape fuel cell performance and manufacturing pathways.

As fuel cell deployment expands in both mobility and stationary sectors, the demand for materials and components used in PEM fuel cells is set to grow in tandem. IDTechEx’s new report, “Materials for PEM Fuel Cells 2026–2036: Technologies, Markets, Players,” delivers detailed 10-year forecasts segmented by application and covering major components in terms of both unit demand and market value.

Alongside these forecasts, the report includes competitive technology benchmarking and trend analysis based on primary research, offering clear insight into the evolving opportunities and challenges shaping this developing market.

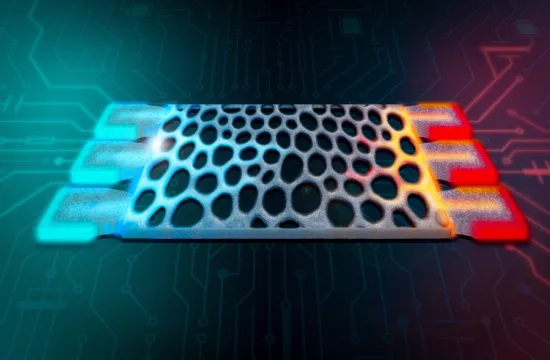

Bipolar plates (BPPs) perform several essential functions in fuel cells, acting as structural elements, current collectors, and separators between hydrogen and oxygen streams. Selecting the right material requires balancing multiple factors such as mechanical durability, corrosion resistance, electrical and thermal conductivity, and overall cost. IDTechEx’s report compares the two dominant material choices, graphite and metal, providing an in-depth assessment of key suppliers, manufacturing methods, and supply chain partnerships with OEMs.

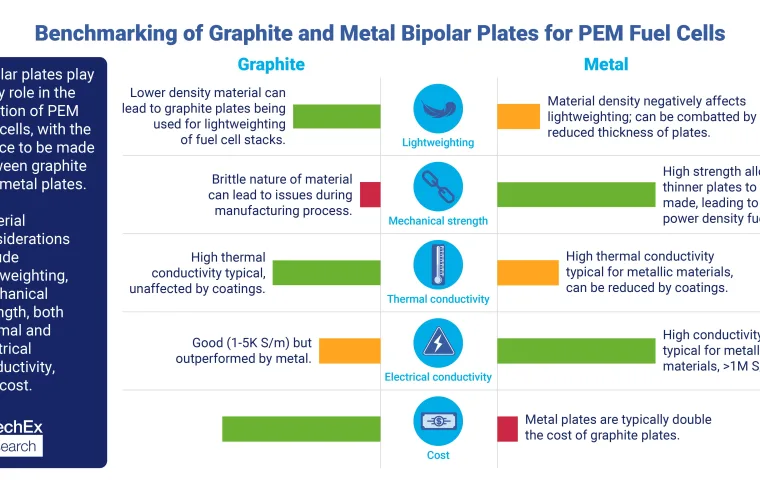

Benchmarking of materials for bipolar plates across a number of parameters. Source: IDTechEx “Materials for PEM Fuel Cells 2026–2036: Technologies, Markets, Players”

Material Requirements for BPPs

Corrosion resistance is important since the BPP is subject to oxidizing and reducing environments on either side of the plate and so must be able to exist in harsh, opposing conditions. High electrical conductivity ensures improved efficiency with respect to gathering current generated in the cell, while thermal conductivity is important for enhanced cooling of the fuel cell stack.

The material chosen must also showcase high mechanical strength. The BPP provides structural integrity to the membrane electrode assembly (MEA), while trends see a continuous reduction in the thickness of the plates for light weighting of the overall fuel cell stack, since BPPs can account for up to 80% of the fuel cell mass.

Graphite or Metal for BPPs?

Assessing the physical properties of BPP materials gives some insights into the use cases in specific applications of PEMFCs. Graphite plates are typically suited to applications where lightweighting is important due to their lower density compared to metal plates. The trade-off is that graphite plates tend to be brittle, which can lead to issues during the manufacturing process, especially for complex flow fields, although this can typically be overcome by using a binder material such as phenolic resins.

A major benefit for metal plates is the increased mechanical strength, allowing thinner plates to be made, leading to higher power density fuel cells. Hydrogen impermeability is also requirement for plates to avoid unwanted gas mixture in the cells, and while hydrogen permeation is low for graphite plates, <10 mol/(cm s bar), metal plates offer superior performance with a hydrogen permeation in the order of 1×10-9 mol/(cm s bar).

When considering the conductivity of the BPPs, both thermal and electrical properties should be assessed. High electrical conductivity is typical for the metals typically used for bipolar plates, including aluminium, steel and titanium, with conductivities often exceeding 1M S/m. This can be compared with the usual value of 1-5K S/m seen for graphite and graphitic composite plates. The narrative is reversed for thermal conductivity where graphite plates typically outperform metal plates, with the anti-corrosion coatings required on metal plates often diminishing the efficiency of thermal conduction.

Outlook for BPPs in PEM Fuel Cells

The primary property not yet considered for BPPs is the cost per plate. IDTechEx analysis of the market, leveraging primary research and interviews with plate manufacturers, provides a detailed projection for the price point of plates over the coming decade, with it expected that metal plates will cost approximately double the price of graphite plates.

This economic benefit is a major driver in the adoption of graphite plates for applications where form factor and power density of the cell are not the primary concern. Graphite plates are most commonly used in heavy duty applications such as trucks, marine and stationary fuel cells. Conversely, metal plates will see significant uptake where power density is of the utmost importance, such as in fuel cell powered passenger cars.