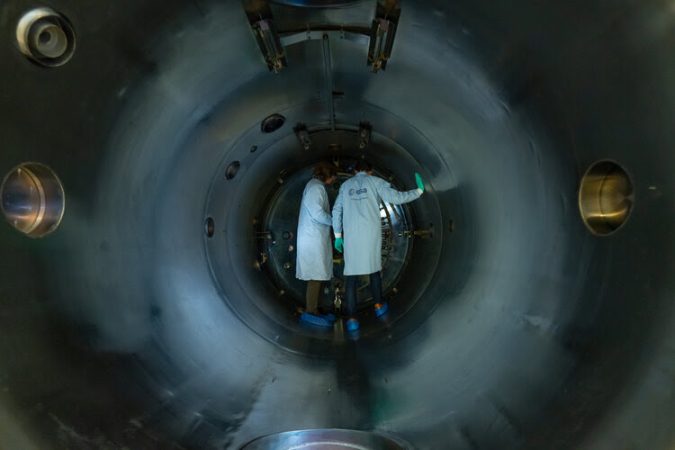

Engineers seen preparing a test inside the largest vacuum chamber of the ESA Propulsion Laboratory – this CORONA test facility measures 2 m in height and 5 m in length – to evaluate a compact electric propulsion design tailored for microsatellites and CubeSats.

According to European Space Agency, Electric propulsion involves accelerating propellant via various electrical or magnetic methods to reach high levels of efficiency – propellant can be ejected up to 20 times faster than a traditional thruster.

Electric propulsion can only take place in vacuum conditions, however, so test chambers are equipped with powerful pumps to evacuate almost all the air, along with coolers to freeze the remainder.

Electrostatic probes, mass spectrometers, and gas analyzers can be used to assess thruster plume characteristics and divergence. Shield-like beam targets and plume diffusers are deployed to prevent potential damage to vacuum chambers from higher-power engines.

Based at ESA’s ESTEC technical center in the Netherlands, the ISO 9001-certified ESA Propulsion Lab is also equipped to test cold gas thrusters and liquid flow and sloshing in engines, tanks, and piping.

The Lab’s objectives include end-to-end testing of CubeSat propulsion systems, accelerating development and testing of new small electric and green-chemical propulsion, developing fluid dynamics and propulsion simulation tools via test validation, and increasing the competencies and training of the coming generation of propulsion engineers.

The ESA Propulsion Lab prioritizes testing for ESA projects but is also available for commercial testing serving ESA Member States companies.