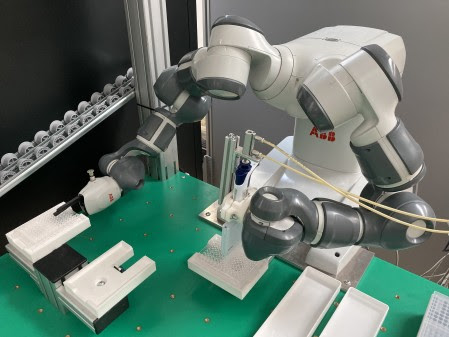

Milan – A robot YuMi can automate up to 77 per cent of the testing actions— helps to analyse up to 450 samples per hour in nominal condition.

YuMi is a ABB’s collaborative robot, was used in an application designed by Politecnico di Milano University, in partnership with IEO to support hospitals in serological testing for Covid19.

According to press release, Andrea Zanchettin, PhD, associate professor at the Department of Electronics, Information and Bioengineering, Politecnico di Milano University, has designed the application and programmed YuMi, a robot capable of automating well plate “pipetting” during serological tests.

The serological test was developed in the laboratories of the European Institute of Oncology in Milan by a group consisting of Marina Mapelli and Sebastiano Pasqualato – two biochemists – as well as Federica Facciotti – an immunologist – based on the protocol created at Mount Sinai Hospital in New York by Florian Krammer.

How does it work?

The robot has two arms: the micropipette is attached to the left one, whilst the right has a “hand” of sorts, with two fingers which are used to handle the plates.

The technician inserts the patient’s serum into a well plate, which is manufactured in such a way that the protein component of the virus, if it is present, adheres to the plastic.

In order for the virus to bond to the plastic stably, a certain incubation period is required. The excess must then be cleaned out of the plate: this is precisely where YuMi comes in.

The technician positions the plates to be washed above a tray with a weight sensor, which notifies YuMi when it is required to activate and “pipette” the cleaning liquid into the wells.

The robot collects the plate and moves it into position, then draws the cleaning solution from a reservoir and fills the plate. It then draws the solution back out of each well and discards it, repeating this operation a total of 3 times: overall, the entire process takes around 3 minutes to complete. At the end, YuMi retrieves the plate and places it on the tray for washed plates.

YuMi is a collaborative robot produced and lent free of charge by ABB as part of the long-lasting, strategic partnership with the Politecnico di Milano known as the Joint Research Centre. It is a multifunctional machine that can be used to ensure repetitiveness in industry and other sectors, such as hospitals and analysis laboratories. YuMi is certified for use in clean rooms (ISO5).

“Robotised collaborative automation has incredible potential in the healthcare sector,” according to Oscar Ferrato, Collaborative Robots Product Manager at ABB. “We at ABB are pleased to have contributed to the development of this interesting and innovative project”.

Politecnico di Milano is a scientific-technological university which trains engineers, architects and industrial designers.