In electric vehicle (EV) batteries, coatings play a critical role in enhancing performance, safety and longevity. They are used on components such as battery cells, busbars, connectors and enclosures to provide insulation, thermal management, corrosion resistance and fire protection. Functional coatings can prevent short circuits, manage heat dissipation and shield sensitive electronics from moisture and chemical exposure.

Emerging technologies, such as ceramic-based layers, can offer cost-effective superior protection compared to traditional inorganic shielding or dielectric tapes. Advanced coatings are increasingly replacing existing solutions, enabling manufacturers to meet stricter safety standards and improve overall battery performance.

IDTechEx’s report, “Advanced Coatings 2026-2036: Market, Technologies, Players”, covers advanced coating technologies for applications in EV battery, oil & gas, aerospace, wind energy, construction, data centers and many more.

Can coatings replace mica shields for fire protection?

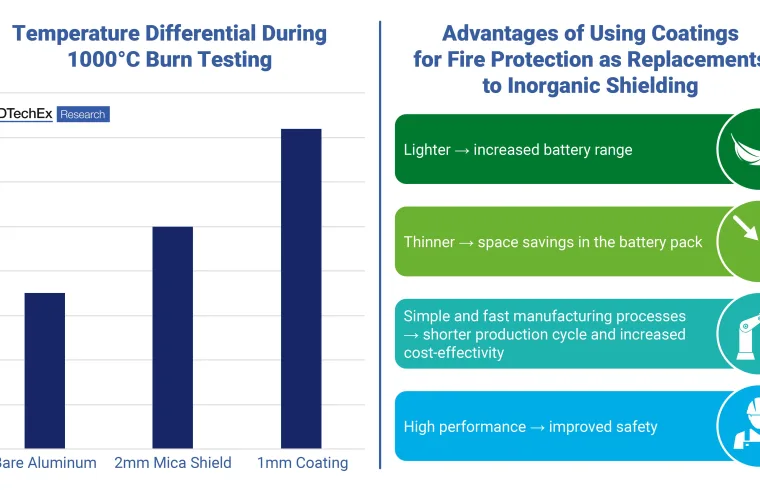

Fire protection coatings such as EV Protect 1000 developed by H.B. Fuller offer strong thermal insulation and cost-effective manufacturing compared to inorganic shielding. Despite this, inorganic shielding still dominates the market with over 90% share.

A key challenge for organic coatings is to improve abrasion resistance under heat, with UL 2596 the standard to be met. H.B. Fuller is developing new formulations to address this, with a launch expected soon. One method to enhance the performance of organic coatings could be to dope them with inorganic materials.

Placement of coatings within EV battery packs varies depending on the specific architecture of the pack. Encapsulating foams are also an emerging option, used around the cells to provide additional protection. Intumescent coatings, which expand upon exposure to high heat to create an insulating layer, are being adapted for battery use with reduced expansion compared to conventional steel coatings, which typically expand around 50 times. This adjustment helps meet the space limitations faced within the battery pack.

Why are dielectric powder coatings gaining traction?

Dielectric powder coatings are gaining traction in EV battery applications due to their multifunctional performance and sustainability benefits. At the Battery Show 2025, IDTechEx witnessed AkzoNobel showcase its Resicoat line, offering solutions for battery packs, cells, cooling plates, motors, and busbars to improve electronic efficiency and prevent short circuits.

PPG and Jotun also presented new dielectric powder coating technologies, highlighting industry-wide momentum. These coatings deliver dielectric strength between 40 and 90 kV/mm and increasingly serve roles beyond electrical insulation, including protection against corrosion, moisture, dust, chemicals and thermal management. This multifunctionality supports compact, lightweight designs and is especially valuable as EV battery energy density rises.

Powder coatings offer clear sustainability advantages: they produce less waste, emit no VOCs, cure faster and at lower temperatures, and are often non-toxic. Their ability to form durable, uniform layers that resist mechanical wear makes them well-suited for demanding EV environments and as a replacement for films and tapes. These benefits, combined with growing regulatory and performance pressures, are driving broader adoption of powder-based dielectric coatings. IDTechEx has noted a market shift from liquid to powder coatings, with AkzoNobel increasing production capacity across North America, Italy, Vietnam, and China.

A lightweight solution to stone chipping

Stone chipping threatens EV battery packs by damaging low-mounted enclosures, leading to corrosion and other safety hazards. To improve stone chipping and corrosion resistance in EV battery packs, manufacturers adopt multi-layer coating strategies. ArcelorMittal begins by applying a metallic zinc alloy coating, such as Zagnelis Protect, to the steel housing, offering sacrificial corrosion protection. This is typically followed by an e-coat layer.

Pfinder’s Water-Based Underbody Protection Coating (WUPC), launched in 2024, can then be added. WUPC adheres to e-coat or organic primers, cures at room temperature, and provides stone impact resistance at thicknesses above 300μm. It also eliminates the need for a separate plastic aeroshield, simplifying the design.

The future of coatings for thermal management?

Battery cooling systems in EVs use aluminum cold plates and embedded tubes to transfer heat away from cells via circulating coolant. While aluminum is thermally conductive, surface imperfections can cause thermal contact resistance. Thermally conductive coatings improve surface contact, enhancing heat transfer and supporting passive cooling.

These coatings typically offer thermal conductivity between 1 and 2 W/m·K and also serve as electrical insulators. First introduced around 2023, they are gaining interest as battery energy density rises. Though not yet widely adopted, several products are now available, and major industry players are actively developing new solutions.

Outlook for advanced coatings in EV battery applications

Future development of EV battery coatings is increasingly focused on sustainability and recyclability. Coatings will be designed to support the recovery of valuable components such as wiring, battery cells, and structural materials at the end of a battery pack’s service life. Incorporating bio-based or recycled content is another direction to reduce environmental impact and improve material circularity.

Beyond sustainability, coatings already offer key manufacturing advantages. They enable shorter production cycle times, reduce costs, increase throughput, and contribute to lighter, more compact designs, critical factors for lowering battery unit costs as electrification scales.

These benefits are expected to drive broader adoption of advanced coatings in EV battery packs over the next decade. For deeper insights into the evolving field of advanced coatings in applications including and beyond EV batteries, see the report “Advanced Coatings 2026-2036: Market, Technologies, Players”.