Major battery energy storage system (BESS) fires have drawn attention to the impacts of Li-ion thermal runaway. These safety incidents can be catastrophic, causing harm to on-site personnel, hazards to health and environments with the release of toxic volatile organic compounds (VOC), and large financial and asset loss. BESS developers are adopting various passive and active thermal management materials and technologies to improve the safety of their Li-ion BESS technologies.

As suggested in IDTechEx’s Thermal Management, Fire and Explosion Protection for BESS 2026–2036: Materials, Technologies and Players, this will be a growing market forecast to reach US$25.4B in value by 2036.

By understanding the root causes and impacts of BESS failure, battery storage players and regulators can target Li-ion BESS technology development with a greater targeted purpose, putting an emphasis on safety to reduce fire and explosion risk. A key pathway to address Li-ion BESS failures could also be with large-scale fire testing (LSFT).

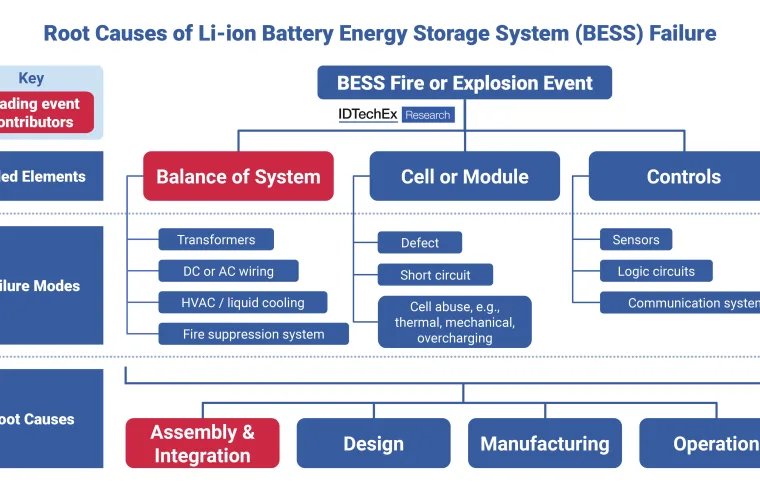

Root Causes of Li-ion BESS failure

The root cause of thermal runaway and failure in BESS can be due to poor design, manufacturing, assembly, and integration, or operation of Li-ion BESS technologies. Many of the BESS incidents recorded globally suggest that integration and assembly of BESS are root causes of failure, with the balance of system (BOS) being a leading contributor.

The BOS could include DC and AC wiring, HVAC subsystems, and safety elements, e.g., fire suppression systems. This was what caused the Victoria Big Battery Li-ion BESS fire, where, during commissioning, a leak in the coolant system led to the fire occurring. IDTechEx’s market report further discusses the other root causes of failure in BESS and key BESS thermal runaway events.

Market Impacts of Li-ion BESS Fires and Explosions

Safety to on-site personnel, civilians, and the environment is critical and, if compromised, could harm the reputation of a BESS developer. Additionally, since battery storage safety incidents are stationary, these can be caught more easily by the media than electric vehicle (EV) fire events, amplifying the damage caused by an event. With the capacity of Li-ion BESS containers and grid-scale project sizes increasing, the severity of thermal runaway events and the impacts on the BESS market could become more severe.

BESS fires have also led to markets stagnating. For example, South Korea faced a reduced number of installed BESS technologies after many Li-ion battery fires in 2018, from which it is now only starting to recover. In such instances, a country is stunted in its progression towards developing a cleaner electricity grid, and this also causes harm to BESS and cell manufacturer business prospects in a particular country.

The financial implications of BESS fires and explosions for the BESS developer can be immense. If these systems are paired in applications with other high-value assets such as data centers, then the financial risk is increased further yet.

Ultimately, if an increasing number of high-value projects become damaged beyond economical repair, this could start to erode wider customer trust in the Li-ion BESS market. In the worst-case scenario, this could lead to some customers starting to turn to safer energy storage (ES) technologies, e.g., redox flow batteries (RFB), even if these come with higher Capex.

How to Address Li-ion BESS Failure and Large-Scale Fire Testing

If a key root cause of BESS failure is due to integration and assembly, this suggests that more stringent checks during commissioning and operation of BESS and workforce training could be key methods to minimize such events. If BOS components are provided by third parties, then further communication between parties may be needed to ensure the entire system operates harmoniously.

Sharing knowledge of BESS failure root causes from the field could improve developer understanding and benefit the wider market, but enforcing such transparency is challenging, as it could unfairly implicate third parties such as cell or component suppliers.

Although advanced sensors and battery management systems (BMS) can help identify failure mechanisms, the complexity and destructive nature of thermal runaway events can prevent precise root-cause determination. Therefore, BESS developers could focus on ensuring systems can effectively react to and contain thermal runaway, using measures like robust fire suppression and gas venting to prevent cascading failures between BESS units.

In fact, many regulations do not require multi-unit or large-scale BESS safety testing. Under UL 9540A, for example, passing a module-level test can exempt higher-level testing. This gap can leave developers unaware of the potential impact of cascading fires in large, GWh-scale projects. However, in the US, the upcoming 2026 edition of NFPA 855 will begin to address this by requiring large-scale fire testing (LSFT) (installation-level test) with UL 9540A to demonstrate that BESS installations can contain thermal runaway without propagation to neighboring units.

Some key BESS developers, including Sungrow, BYD, and Huawei, have started conducting large-scale fire tests. Sungrow invested over US$4M to conduct one of these tests on a 20 MWh PowerTitan 2.0 unit. Ultimately, LSFT for BESS could be a trend that spreads globally and should promote safer Li-ion BESS systems, but this will come with added costs for BESS developers.