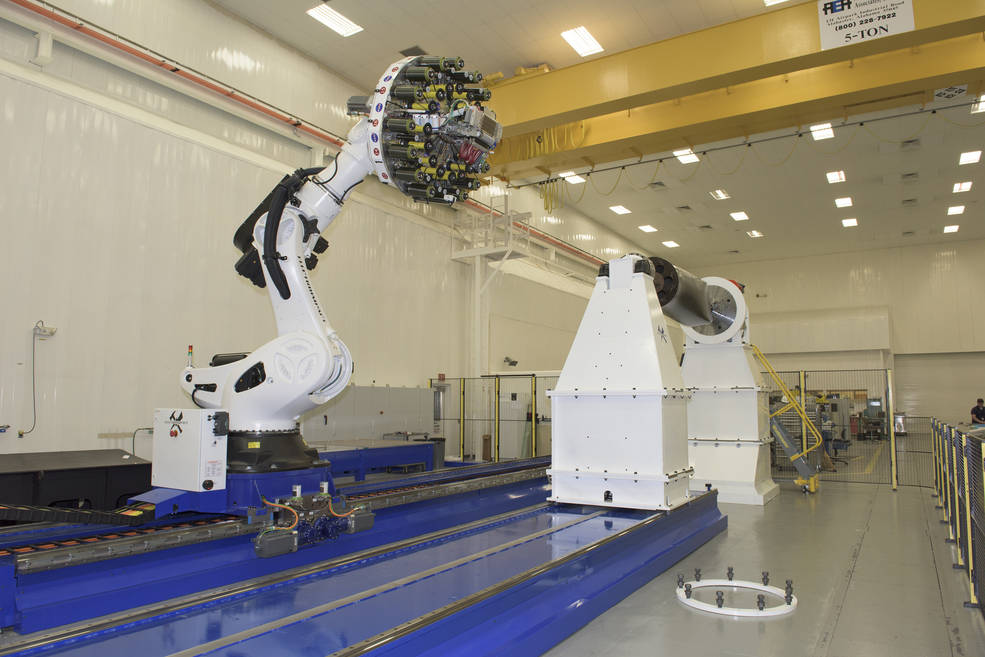

Credits: NASA/MSFC/Fred Deaton

Deputy Administrator Dava Newan will tour NASA’s National Center for Advanced Manufacturing Composites Technology Center at 2:30 p.m. CDT, Thursday, Aug. 6, during a visit to the agency’s Marshall Space Flight Center in Huntsville, Alabama. There, she will see a new robotic fiber placement system slated to develop processes for building the largest composite rocket parts ever manufactured.The tour will take place in building 4707.

Newman and Jeffrey Sheehy, senior technical officer in the Space Technology Mission Directorate at NASA Headquarters in Washington, will join Marshall Center Director Patrick Scheuermann; Chris Singer, director of Marshall’s Engineering Directorate; and John Vickers, manager of NASA’s National Center for Advanced Manufacturing, to see the robot and other facility equipment for making composite structures.

NASA is developing capabilities that enable more affordable, lightweight materials and processes for infusion into its unique missions, systems and platforms. Lightweight composites have the potential to increase the amount of payload carried by a rocket as well as lowering its total production cost. NASA is conducting composites manufacturing technology development and demonstration projects that are applicable to the Space Launch System, a heavy-lift rocket designed to take explorers on deep space missions, including to an asteroid and Mars.