Researchers have developed a novel method to dehydrate fruit at room temperature—eliminating the need for energy-intensive heat.

The technique, reported in ACS Food Science & Technology, uses food-safe calcium chloride and adjusted air pressure to dry fruit slices efficiently while preserving their color and texture.

Traditional dehydration methods rely on circulated hot air or solar drying, both of which have drawbacks: high energy consumption or slow, uneven results. Seeking a more eco-friendly alternative, Luis Bastarrachea and his team designed a no-heat drying chamber that leverages calcium chloride’s moisture-absorbing properties.

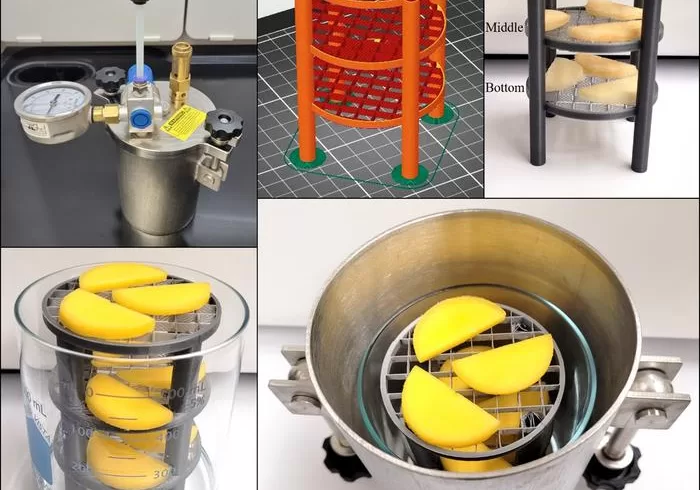

The chamber features three tiers of screens positioned above a container of calcium chloride solution, where mango and apple slices were placed for testing.

The researchers compared two drying conditions—standard air pressure and a slight vacuum. After four days, fruit dried under vacuum retained a consistent moisture level of about 30%, matching commercial standards. In contrast, slices dried at normal pressure showed uneven results, with moisture levels ranging from 20% to 70% depending on their placement in the chamber.

Notably, vacuum-dried mango slices maintained their vibrant yellow hue, while both methods caused similar darkening in apples. Microscopic analysis revealed that vacuum drying also helped preserve starch granules, indicating slower deterioration and better freshness retention.

The innovation goes beyond fruit preservation. Bastarrachea notes that the water extracted during the process can be recovered and reused: “The collected water in the calcium chloride solution can be removed by evaporation, and the reconcentrated calcium chloride solution can be reutilized in more dehydration cycles.” This opens the door to potential industrial reuse or even treatment for human consumption.

The study was supported by the U.S. Department of Agriculture’s National Institute of Food and Agriculture through the Agriculture and Food Research Initiative.