Fluorescent polymer points the finger at traces of explosive devices.

Bomb plots could be thwarted with the help of a portable system for detecting traces of high explosives using fluorescent polymer nanoparticles [1], developed by A*STAR. Coated on to paper, these polymers display an explosive-detection performance far more robust than previous materials with similar properties.

Many methods have been developed to detect traces of high explosives such as trinitrotoluene (TNT), but most require large, lab-based analytical instruments such as UV absorption detectors or mass spectrometers, says Jianwei Xu from the A*STAR Institute of Materials Research and Engineering, who led the work. “We aimed to develop a portable, quick, inexpensive and highly sensitive alternative.”

Xu focused on fluorescent polymers whose light emission dims when exposed to vapors of molecules such as TNT that contain ‘nitro-groups’ — the nitrogen-rich structure that give high explosives their energetic properties.

Although explosive-detecting fluorescent polymers have been developed before, there have been obstacles to their practical use, Xu explains. Some lost part of their fluorescence in solid form through a process called aggregation-caused quenching. Others lacked the necessary porosity for explosives vapor penetration, only retaining an effective response when formed in layers of around 2.5 nanometers — so thin, the sensor would be very difficult to fabricate cheaply.

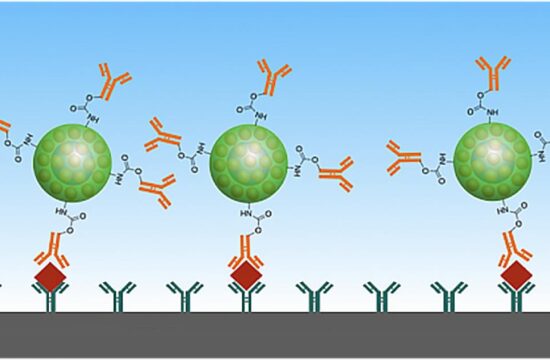

Xu and his colleagues have been developing polymers that, rather than losing their light emission in the solid state, become brighter, an effect known as aggregation-induced emission (AIE). “Our previous research demonstrated that porous films obtained from AIE active copolymers show a strong response to the vapor of nitro-compounds,” says Xu. The team has now developed two new polymers, poly(triphenyl ethene) (PTriPE) and poly (tetraphenyl ethene) (PTPE), designed to maximize AIE, porosity and nitro group sensitivity. The polymers’ multiple bulky phenyl groups help keep them rigid and maximize light emission following aggregation. But in the presence of nitro-groups, electron transfer between polymer and analyte rapidly quenches the light.

“Paper sensors fabricated by absorbing the polymer nanoparticles on to filter paper showed high sensitivity for nitro-compound particles,” says Xu. PTriPE proved to be the pick of the pair, detecting TNT at a concentration of five parts per billion, even in polymer layers 1000 nanometers thick.

“This technology could be used at airports, ports and for border control for detecting explosives in any explosive-contaminated containers, clothing, boxes or bags,” says Xu. “We are seeking co-operation with industry to commercialize this technology.”

The A*STAR-affiliated researchers contributing to this research are from the Institute of Materials Research and Engineering.