Contact lenses, spectacles and eye implants are now being made more accurately thanks to research instruments flying on the International Space Station.

Contact lenses, spectacles and eye implants are now being made more accurately thanks to research instruments flying on the International Space Station.

With the competitive lens market offering increasingly complex products such as varifocal and high-definition contact lenses, precisely shaping a lens is critical.

Every lens must be thoroughly checked to ensure it has been made according to the patient’s prescription. Belgian company Lambda-X came up with a space-inspired device to do just that.

A long-term partner of ESA, they converted an instrument they had developed for space use into a quality-control tool that has significantly improved the products.

Sitting at the end of the production line, it precisely checks the whole lens – including the inside.

It can even inspect lenses that surgeons implant to improve the vision of patients with cataracts.

“One of the biggest challenges when making any kind of lens is getting the shape right every time,” says Marc Halbach from Lambda-X customer PhysIOL.

“Misshapen or defective lenses can cause discomfort and distort vision. Unlike contact lenses, you cannot throw away a lens that is inside your eye if it’s not right. It’s vital for us to ensure each lens meets our stringent quality threshold.”

From weightlessness to clear vision

Lambda-X has developed and built more than 30 optical and measuring instruments that are either already in space or set to go.

A compact unit on ESA’s Trace Gas Orbiter will soon be analysing the martian atmosphere, and there are various instruments in the laboratories on the International Space Station.

One Station instrument is monitoring the behaviour of liquids and gases in weightlessness.

“Out of curiosity, I put my glasses into the unit,” recalls the company’s CEO, Olivier Dupont. “We realised quite by accident that we could also measure optical lenses and surfaces very precisely.”

They came up with a machine that inspects ophthalmic lenses with far greater accuracy than its competitors, and it has been so successful that the company has become a world leader in the field.

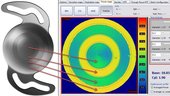

Mapping the lens

The technique maps not only the surface of the lens but also its interior.

“Next time you watch sunlight travelling through the hot air above a candle or a toaster onto a bright wall, notice how grey streaks whirl around like smoke.

By observing the shadow, we can measure the optical properties of the hot air – or lens, in our case.”

There is a benefit in time and manpower because operators no longer need to calibrate the devices as they do with older methods, and the software is easy to use with plenty of options and full traceability.

For Lambda-X, working with manufacturers like PhysIOL has allowed both sides to improve their service.

“We’ve learned a lot from Lambda-X and they have gained from us. It’s a mutually beneficial process of technology and knowledge exchange that has been instrumental in our latest breakthroughs in implant lenses,” says Marc Halbach.

In future, Lambda-X hope their instrument might sit on your optician’s desk to check that your glasses or lenses are, indeed, what you ordered.

“Working in space is a dream come true for us,” ponders Olivier Dupont. “If we can use that expertise to help improve people’s vision then I guess we are, in our own small way, helping some folk to have better lives.”

“This is one of many transfers from space technology that make a difference here on Earth,” notes Sam Waes from Verhaert, the Belgium broker to ESA’s Technology Transfer Programme, which helps industry to take advantage of technologies developed for Europe’s space programmes.

“Thanks to this transfer, the quality control of corrective vision lenses is stongly improved. In particular, this is a great improvement for an implanted lens replacing the eye’s natural lens when it is removed during cataract surgery, or if used in vision-correction surgery.”